Dry-contact electrodes make EEG faster to set up and easier to reuse. No more gel, no more sticky set ups, no more unhappy participants leaving the lab with dirty messy hair, and no more extra time needed for the cap to dry in between subjects. Dry electrodes allow fast, easy access to Electroencephalography (EEG) data, making it portable and fully mobile, to carry out research even in the field.

But before jumping into the world of mobile and dry-EEG, there are several aspects to consider. One of the most important choice, often overlooked, is the electrodes material. Not all dry-contact electrodes are the same. The material you pick shapes everything, from comfort to impedance to lifetime to costs.

Below is a quick tour of common options, why we use gold-plated pins at BrainAccess, and a preview of the SoftPulse® soft electrodes from Datwyler that we’re adding as an optional accessory in our next release.

Why materials matter

At the skin-electrode interface, you’re balancing electrical performance (impedance, noise), mechanics (stiffness, conformity, pressure), biocompatibility, cleanability, and cost. Rigid metals often win on stability and longevity; soft elastomers win on comfort but can have higher impedance and finite lifetimes. Reviews of wearable electrode design consistently show that no single material dominates across all dimensions, as structure and surface texture matter as much as the base material.

A (non-exhaustive) material map for dry electrodes

Dry electrodes can come in different materials and shapes. Below, a non-exhaustive list of materials currently used in the field and available in the market.

Carbonaceous materials

The most common material for dry electrodes due to reduced costs, low density, chemical stability, and tunable roughness. Some examples:

- Carbon nanotubes (CNTs): Known for high conductivity and mechanical strength, often dispersed in a polymer matrix to create electrodes.

- Graphene: Another material with excellent conductivity and flexibility, also often used in composite structures.

- Carbon black: Can be incorporated into electrodes for improved conductivity.

Disadvantages: process variability; coatings can be fragile if not well anchored.

Metals and coating

While not as common as carbon-based materials due to cost and processing challenges, metals like gold (often gold-plated), titanium, or platinum are used in some dry electrodes (yes, including ours). These electrodes type is the most durable, resistant to corrosion, easy to clean, and compatible with textured or multipin geometries for hair penetration. Here’s the most common types of metal used:

- Gold (Au) or Gold-plated materials: used for increased electrode durability

- Titanium (Ti) and Platinum (Pt): particularly used in specialized forms like porous layers or thin films.

- Silver (Ag): popular choice due to its high conductivity, often used in the form of silver yarns, silver paste, or silver nanowires

- Ag/AgCl, TiN, IrOx as functional coatings

Disadvantages: rigidity can reduce comfort without careful geometry, shape-conforming features, and controlled preload (initial pressure).

Conductive polymers

This type of material is highly conductive and flexible, making it good to explore for EEG applications. Often used as thin films on metals or textiles. Their main advantage is lower modulus and improved interfacial charge transfer. Some examples:

- PEDOT:PSS: A commonly studied polymer for dry electrodes.

- PDMS (Polydimethylsiloxane): A flexible polymer often used in conjunction with other conductive materials like PEDOT:PSS.

Disadvantages: hydration sensitivity, long-term stability is low.

Conductive elastomers and silicones

This material is used in some dry electrode designs for flexibility, comfort, and conformity. They usually come in dome/brush shapes, to help penetrate through the hair. The SoftPulse electrodes by Datwyler are a good example.

- Silicone/TPU rubbers filled or coated with conductive phases (e.g., Ag/AgCl-coated conductive elastomer)

Disadvantages: typically higher impedance than stiff pins at the same pressure; finite wear life.

Textiles and films

Made by integrating conductive yarns into fabrics or by applying conductive materials to textiles. They can cover a large area, and allow for comfortable and breathable wearables, ideal for long wear and/or sleep research. Examples include:

- Silver-plated nylon

- Stainless yarns

- ITO or conductive inks on flexible films

Disadvantages: sensible to coupling pressure and motion artifacts.

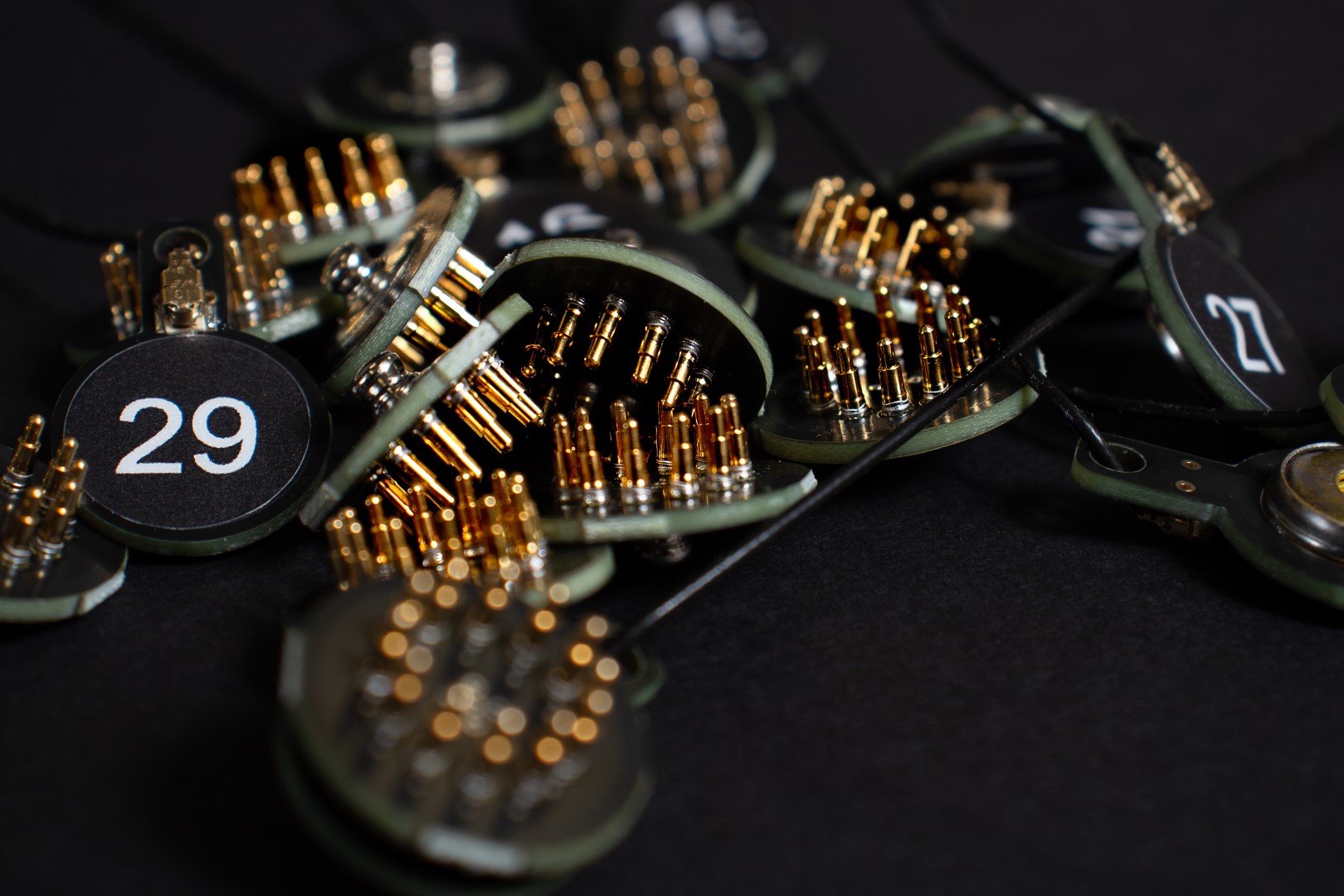

What we use at BrainAccess

We manufacture our own gold-plated dry electrodes in-house. We chose this material prioritizing resilience and functionality.

- Durability and corrosion resistance: our electrodes are built to withstand repeated use, frequent cleaning, and the rigors of transport. Since BrainAccess systems are fully portable, the electrodes must handle being packed, carried, and handled without losing performance.

- Stable impedance over time: Gold is chemically inert and highly resistant to oxidation, which means its surface properties remain consistent even after repeated use and cleaning. This ensures reliable signal quality and reduces variability across sessions, especially important in dry-contact systems where no conductive gel is used.

- Biocompatibility and consistent surface chemistry: Gold is widely regarded as one of the most biocompatible metals. It doesn’t react with skin or bodily fluids, making it ideal for prolonged contact. Its stable surface chemistry ensures minimal irritation and consistent electrode-skin interaction, which supports reliable, repeatable recordings.

We also texture the contact surface with nano-scale “sprinkles” (nanostructuring) to increase the effective area and penetrate through the hair.

Moreover, we’re now testing larger pins to maintain signal quality through dense or curly hair while reducing local pressure per pin for better comfort.

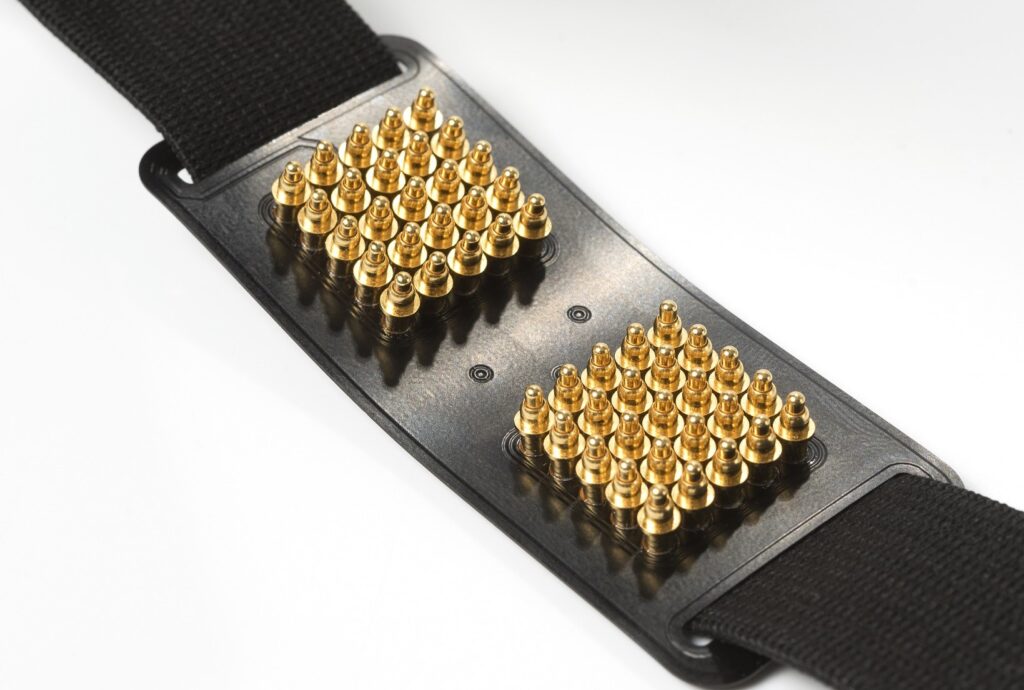

What’s coming: SoftPulse® soft electrodes by Datwyler (optional add-on)

In our next release, we will offer SoftPulse® soft dry electrodes as an accessory for customers who prioritize comfort (e.g., longer sessions, sensitive skin, non-hairy sites). SoftPulse uses a conductive elastomer body with a silver/silver-chloride (Ag/AgCl) contact, with typical skin impedance reported in the ~25–300 kΩ range. Designs include flat and brush geometries for non-hairy and hairy regions, respectively. Moreover, SoftPulse electrodes come in different shapes, to accommodate different hair lengths. (Find out more about the available designs on Datwyler website).

Why they’re more comfortable

- Low modulus, high conformity: the soft elastomer spreads pressure, reducing hot spots compared with rigid pins.

- Geometry options: brush tips help reach the scalp through hair with lower force; flat pads excel on temples, forehead, or behind the ear.

Note that we do not recommend to mix this electrode type with Neurotechnology’s ones. Within one cap set up, all channels need to be consistent in material.

The trade-offs (what to expect)

- Higher impedance than rigid, sharp metal pins at equal pressure

- Finite lifetime: soft coatings and elastomers age with cleaning and abrasion. Datwyler markets abrasion stability “even after hundreds of applications,” but real-world lifetime depends on handling and cleaning chemistry. We plan to rate the add-on for ~100+ uses in our own guidance.

Conclusion

No single electrode material is perfect, each comes with trade-offs between comfort, signal quality, durability, and usability. At BrainAccess, our default gold-plated, nano-textured pins are designed to strike a solid balance for robustness, long-term stability, and ease of cleaning, making them ideal for both research labs and developers working on real-world applications.

For users who prioritize comfort and skin conformity, our upcoming SoftPulse® add-on provides a compelling alternative. Made from conductive elastomer with Ag/AgCl contact, these soft electrodes offer a gentler touch, especially useful for long sessions or sensitive skin, while clearly defining the expected trade-offs in terms of impedance and lifespan.

But we’re not stopping here. We’re actively exploring new geometries to further enhance comfort, durability, and signal fidelity. Our goal is to continuously improve the wearability and performance of dry-contact EEG—because great data starts with great sensors.

Written by Martina Berto, Research Engineer and Neuroscientist for BrainAccess at Neurotecnology.

Reference

Lim, K., Seo, H., Chung, W. G., Song, H., Oh, M., Ryu, S. Y., … & Park, J. U. (2024). Material and structural considerations for high-performance electrodes for wearable skin devices. Communications Materials, 5(1), 49. https://doi.org/10.1038/s43246-024-00490-8

Yang, L., Liu, Q., Zhang, Z., Gan, L., Zhang, Y., & Wu, J. (2022). Materials for dry electrodes for the electroencephalography: advances, challenges, perspectives. Advanced Materials Technologies, 7(3), 2100612. https://doi.org/10.1002/admt.202100612

Fu, Y., Zhao, J., Dong, Y., & Wang, X. (2020). Dry electrodes for human bioelectrical signal monitoring. Sensors, 20(13), 3651. https://doi.org/10.3390/s20133651